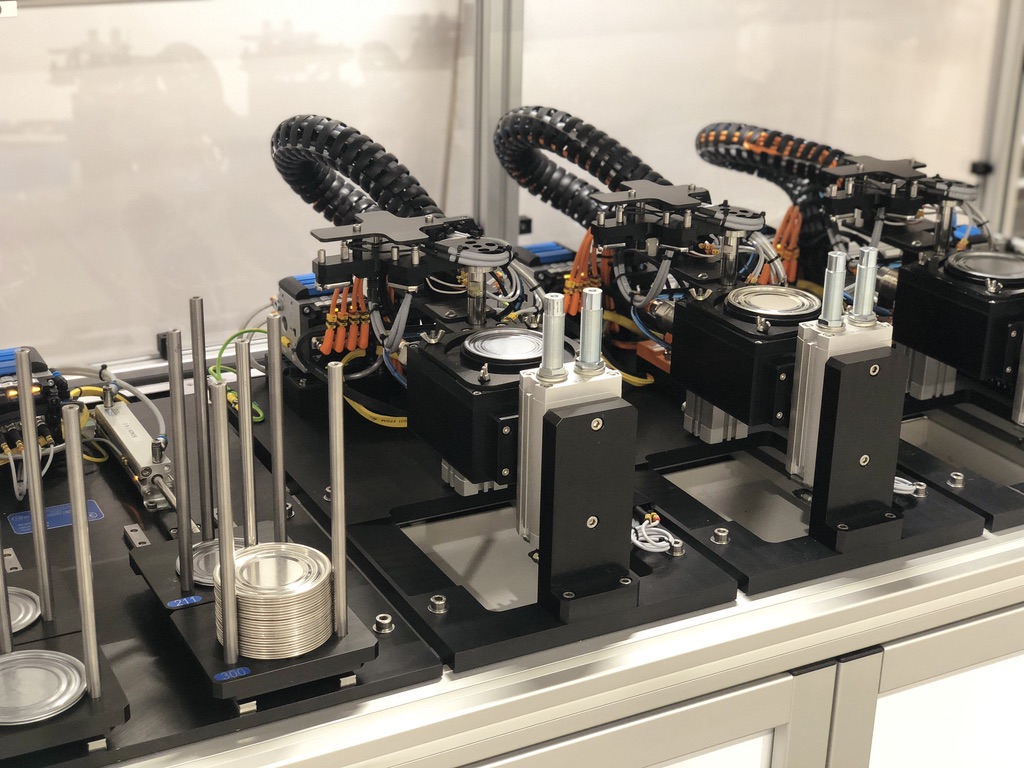

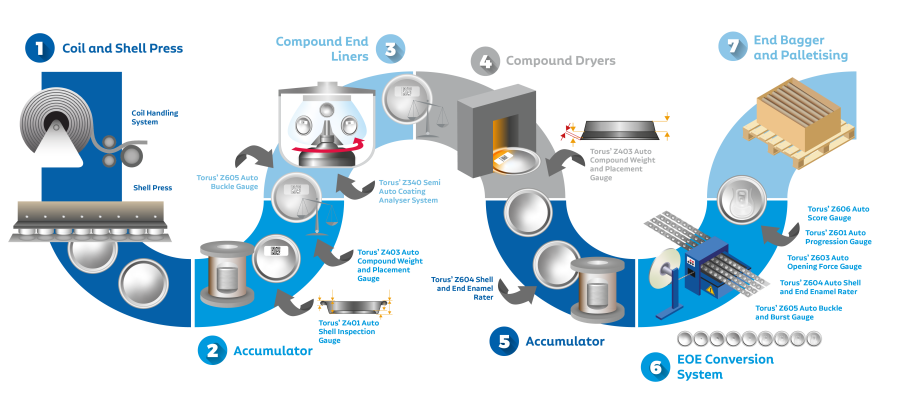

Our Z604 Automatic Food Shell and end Enamel Rater offers unprecedented functionality and capability for today’s global shell/end-making industry.

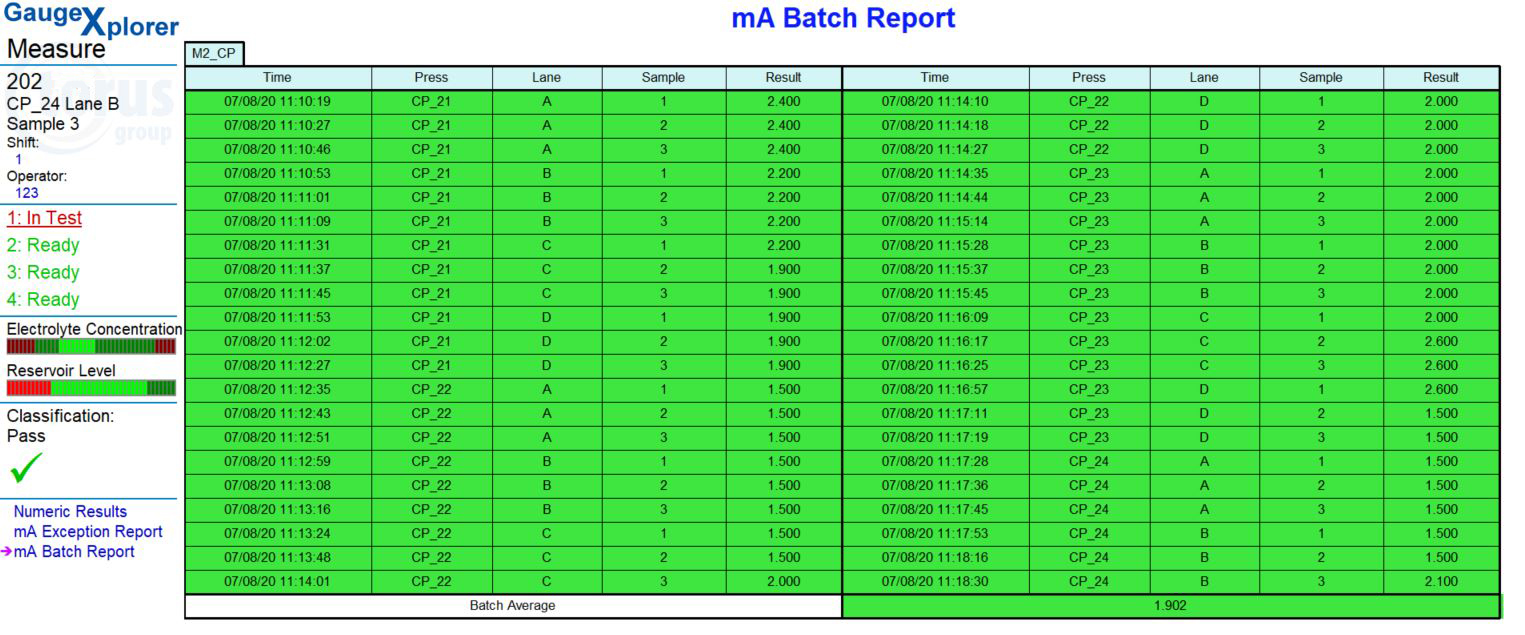

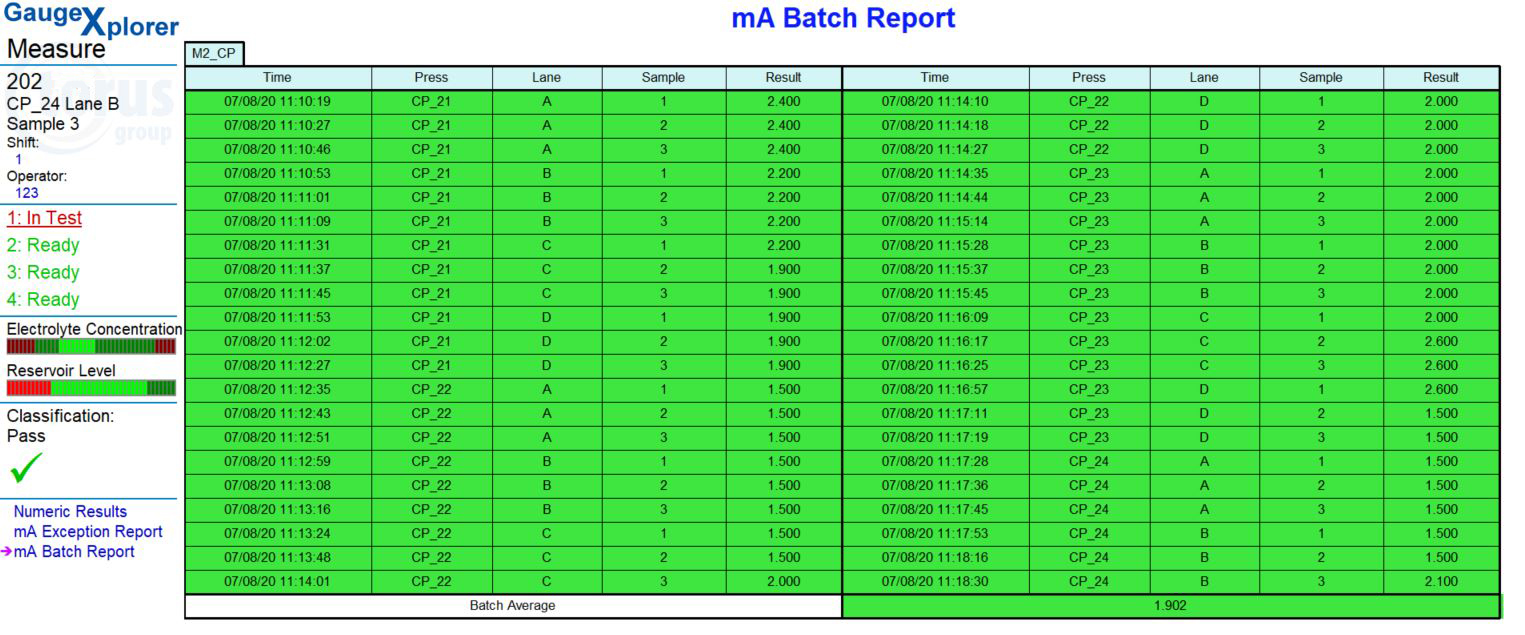

By monitoring critical manufacturing parameters over time and relating the press performance to the change in the ends opening signature, the manufacturing process capability can be observed. This trend monitoring is extremely beneficial to the process engineer, in predicting potential out-of-spec score residual and other critical features. By sampling ends from the production line, the Opening Force Gauge can monitor tooling wear in real-time and provide significant savings in both labour and scrap.

Measurement Features

Technical Specification

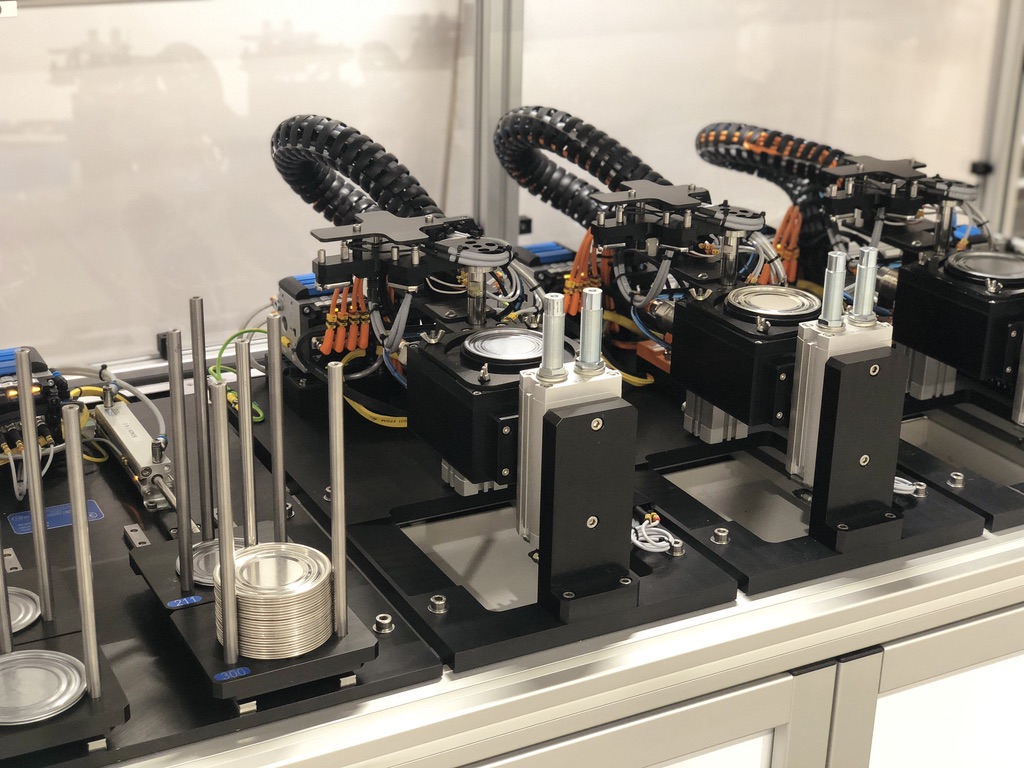

Once the part program is selected, the operator will be prompted to load the hopper system as instructed, a maximum of up to 100 shells / ends per hopper (maximum of 4 hoppers per gauge)

The samples can be collected from the production lines and batch loaded at any given time without cancelling the current batch inspection sequence, resulting in increased sample testing frequency.

The gauge will then automatically start the test cycle using the industry standard 4 second procedure.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999