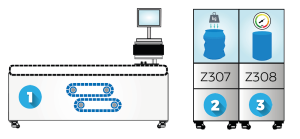

Torus’ Z307 series defines the standard for destructive testing and inspection

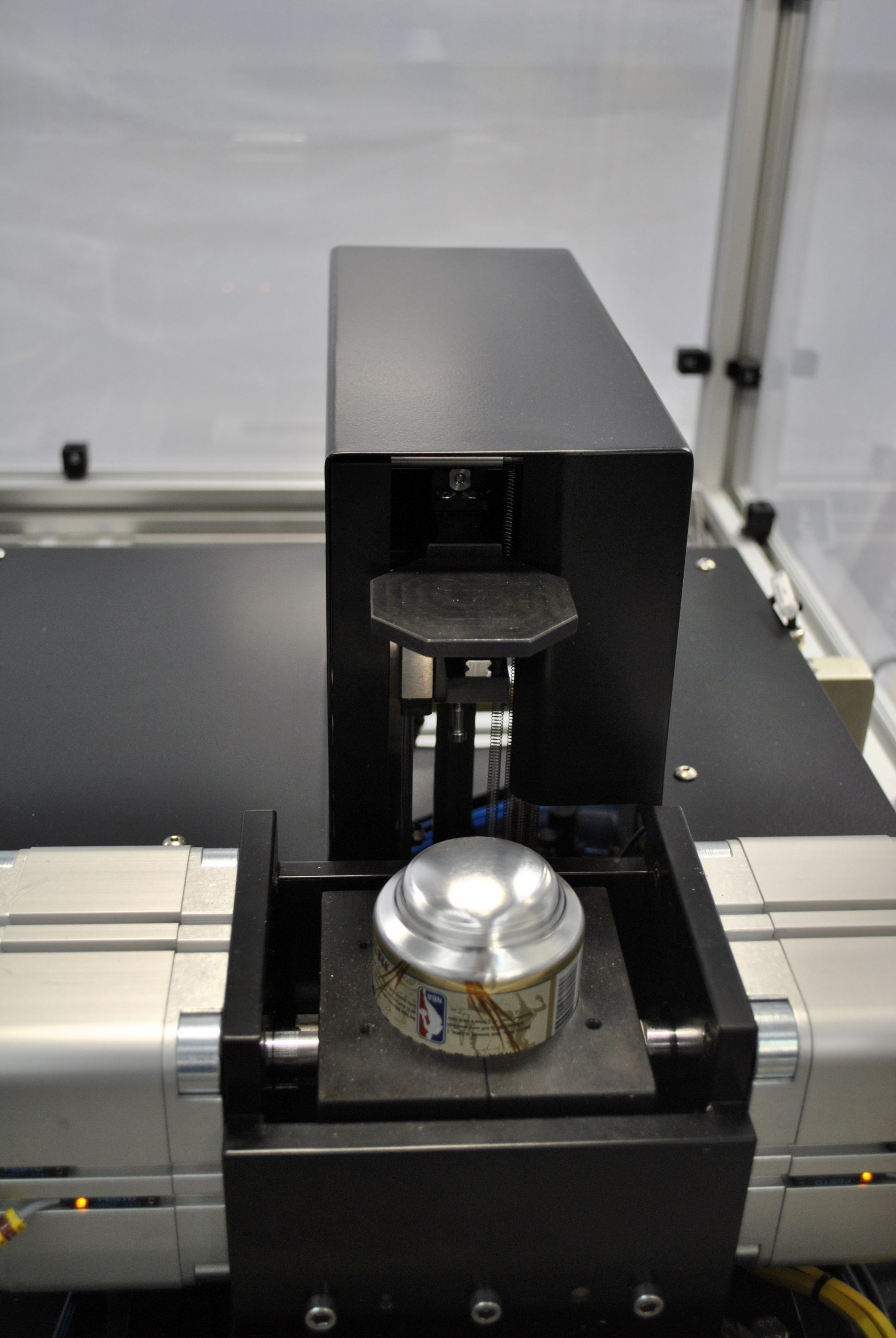

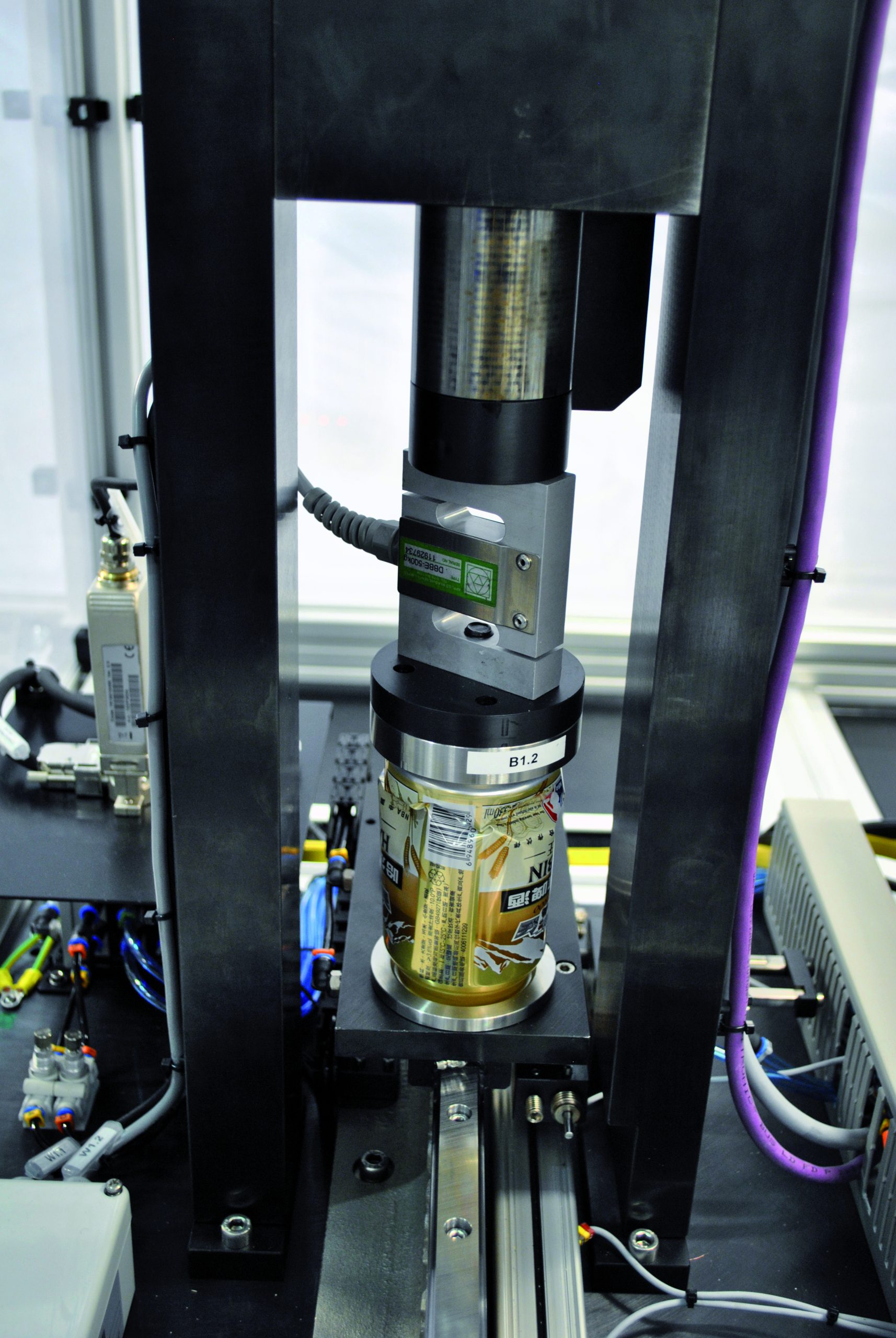

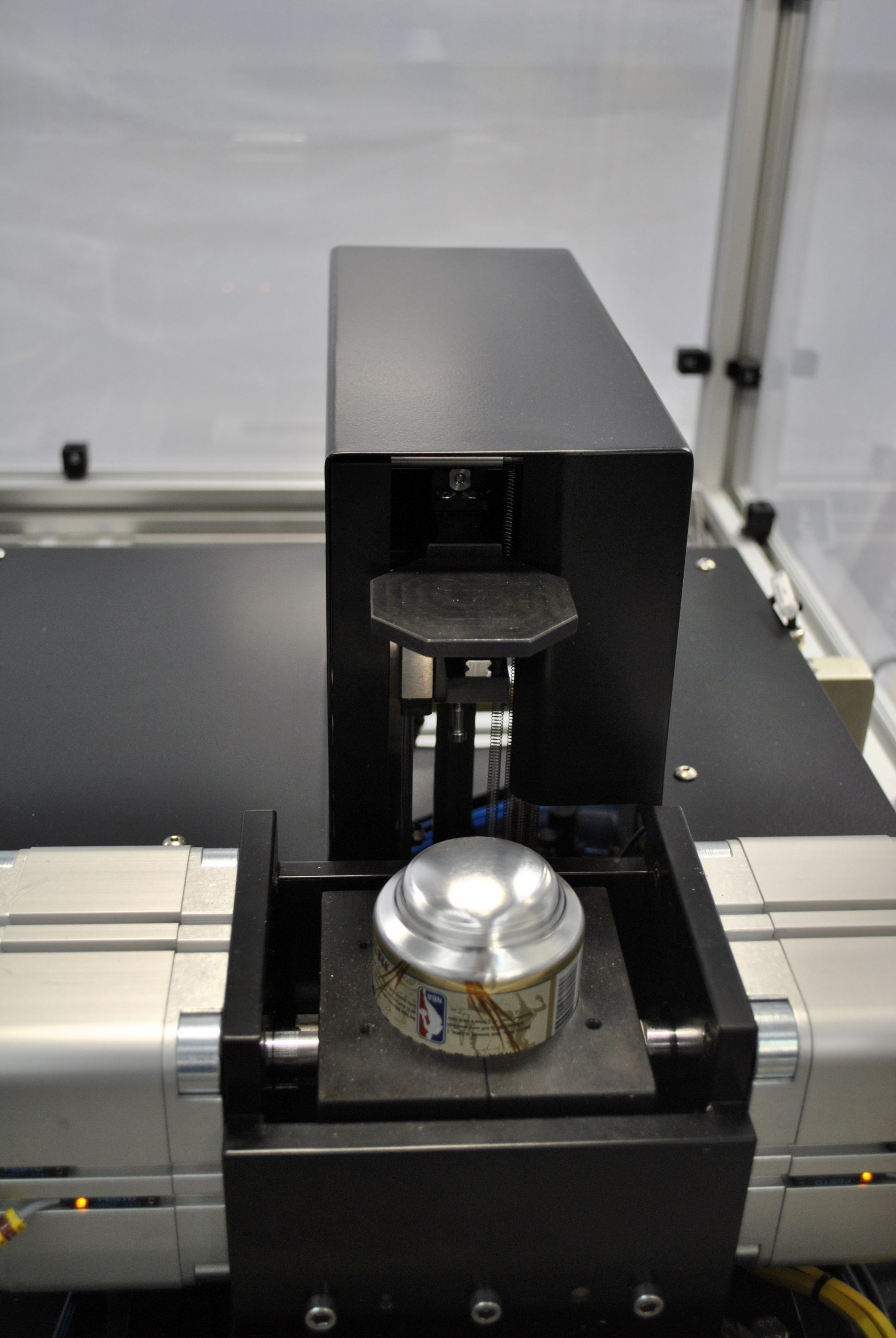

The Z307 Automatic Axial Load module determines the maximum axial load force that can be applied prior to container failure, within a short cycle time.

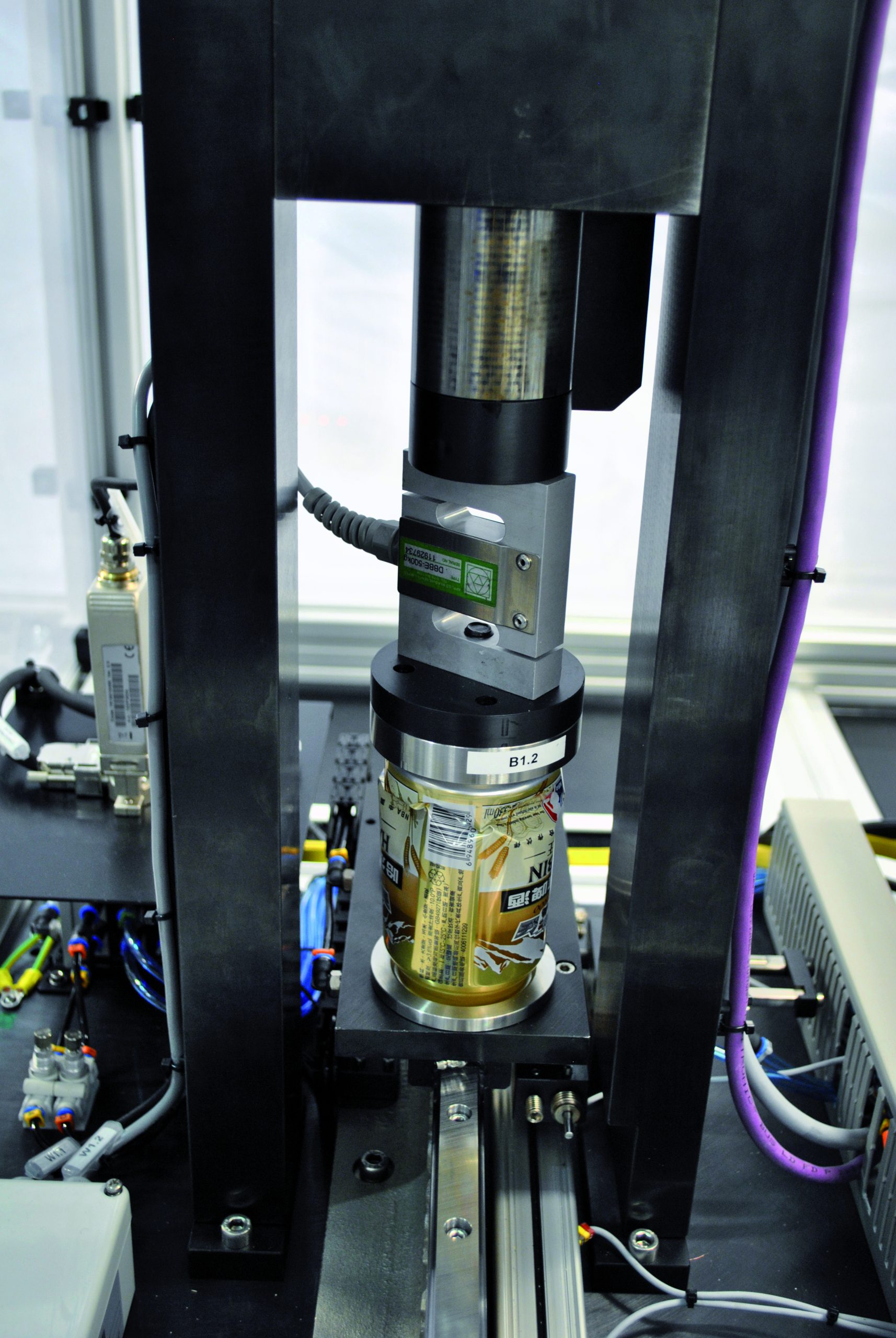

The Z308 Dome Growth/Dome Reversal module provides detailed information about the overall change in length of the can when pressure is applied and subsequently removed. The system has programmable internal pressure capability to meet each customer’s exact needs for dome growth. After dome growth, the can sample can be reversed to find the maximum pressure the sample is able to withstand before failure (dome reversal)

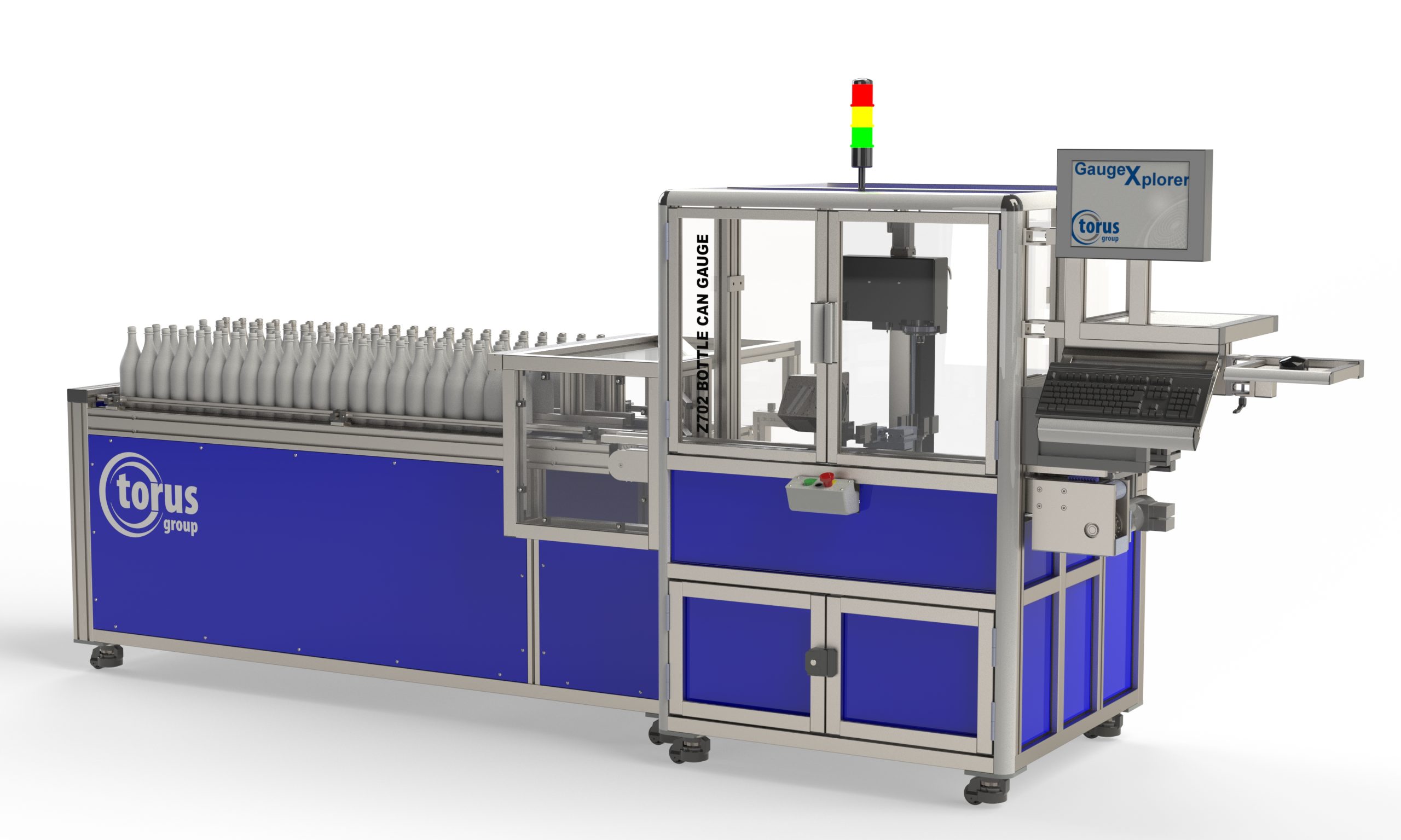

Torus Beverage Can Gauging

Measurement Features

Technical Specification

Gauge Features

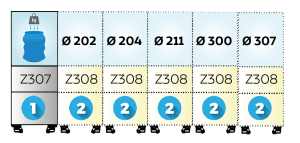

Option 1: Standard Setup

Z308 Option:

Interchangeable Jaws

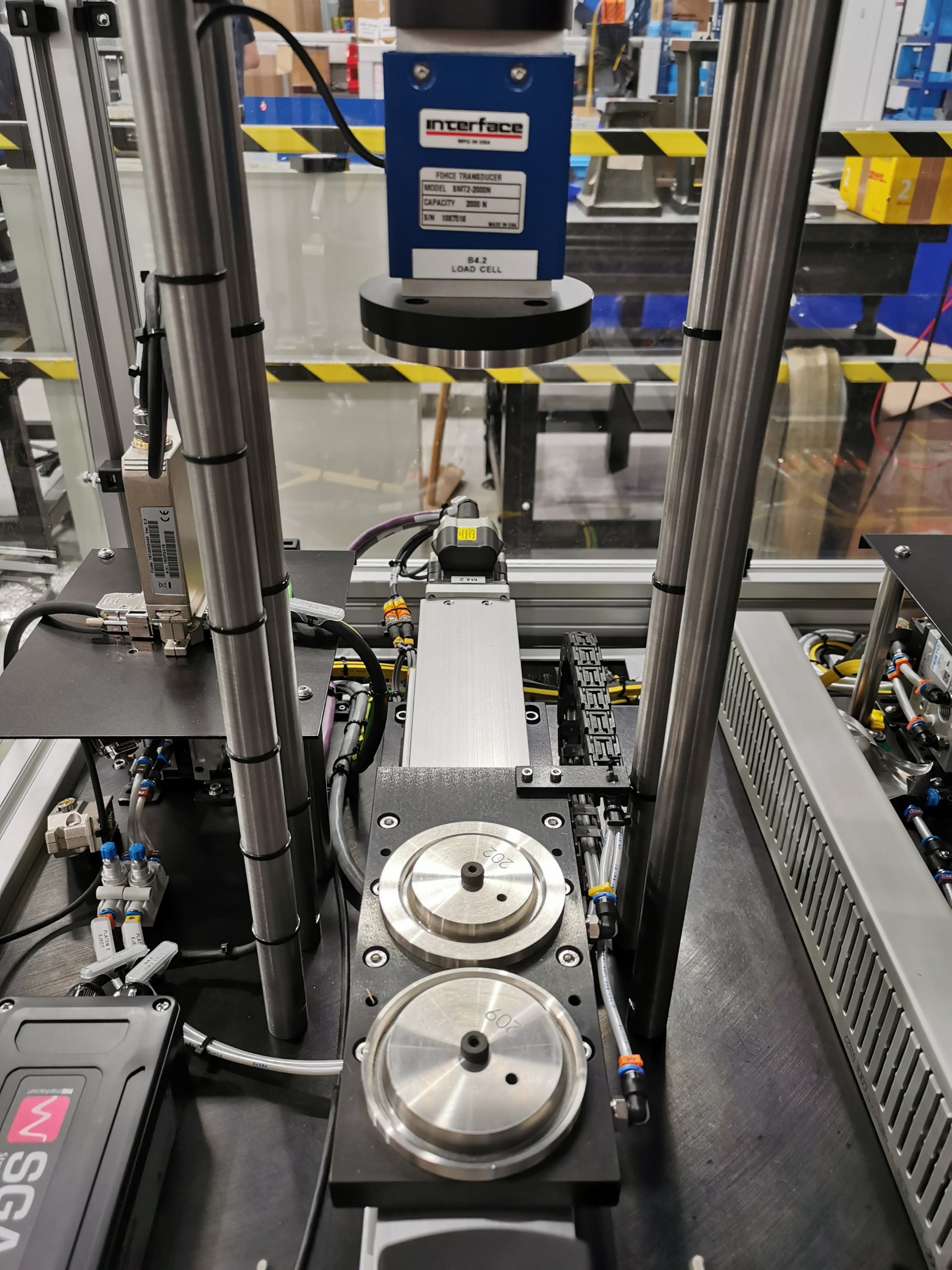

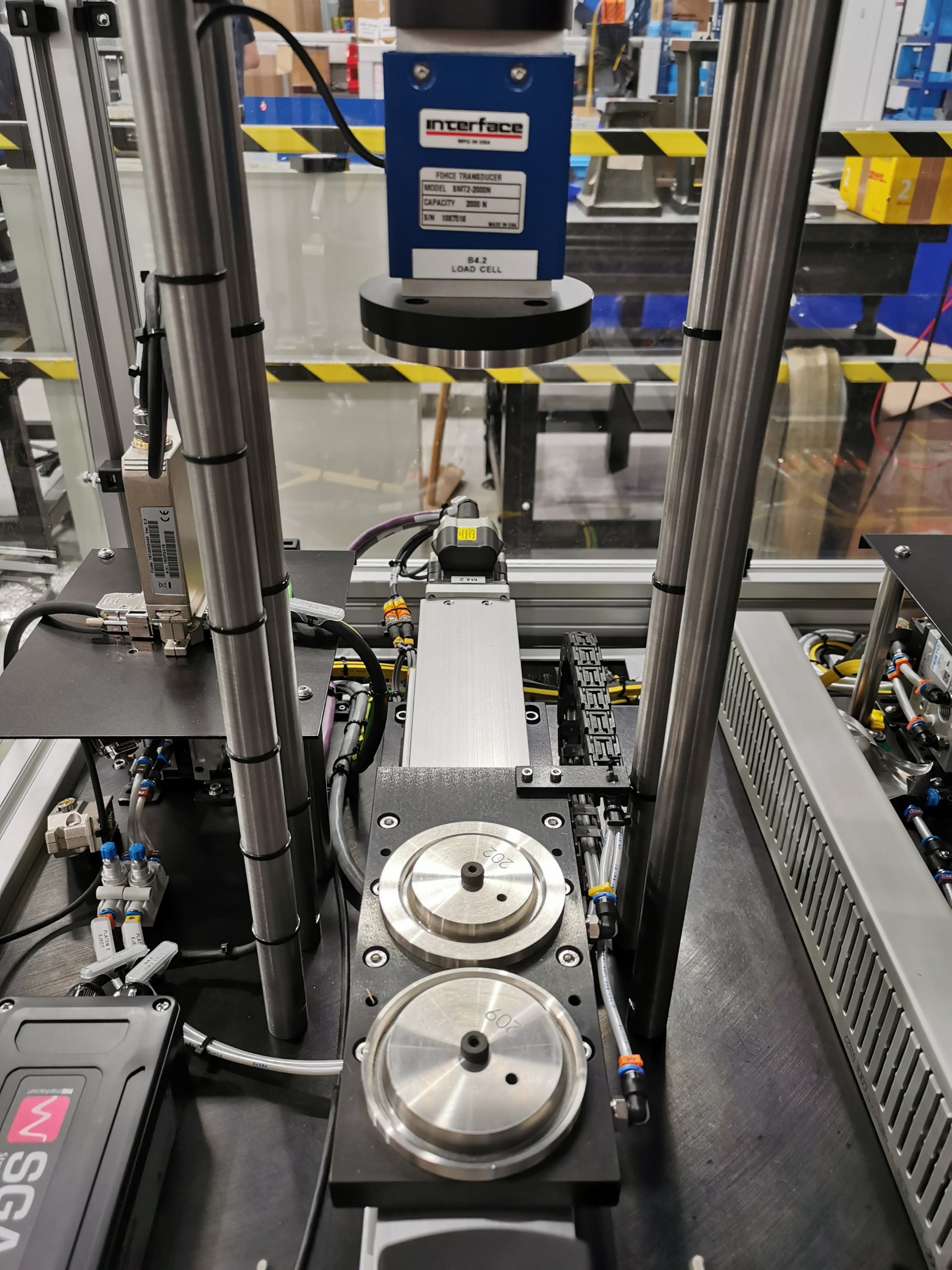

Option 2: Dedicated Body Diameters

For dedicated body diameter product lines, the Torus modular concept is able to cover Ø 202 – Ø 307 body diameters (up to but not limited to) with a dedicated module for each with no change parts.

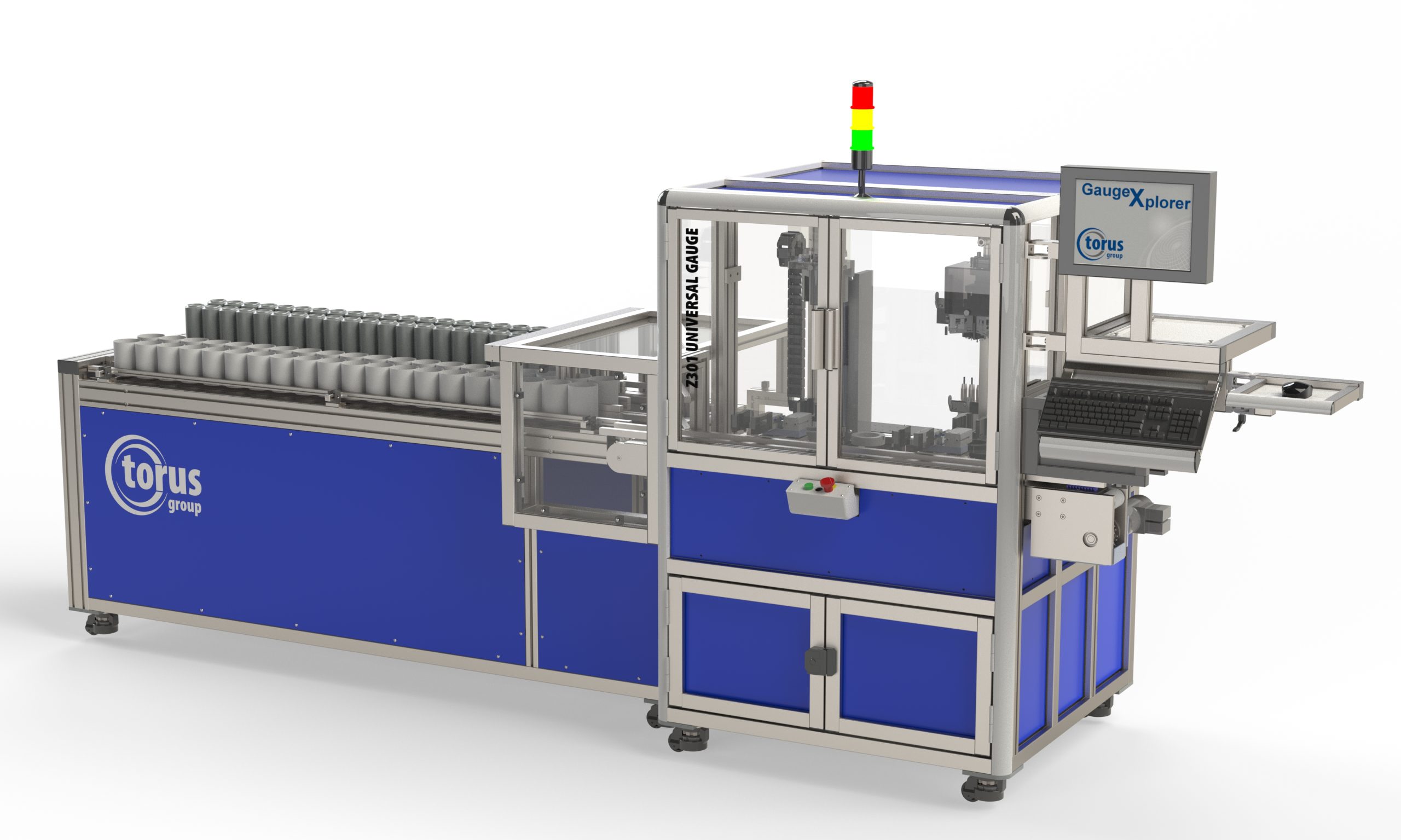

The Z301 Universal Gauge incorporates trimmed and finished can measurement into the same system, for full component measurement.

The proven contact measurement technology ensures accurate, reliable and traceable measurement 24/7.

Torus Beverage Can Gauging

Measurement Features

Trimmed Can Features

Finished Can Features

Technical Specification

Trimmed Can Capabilities

Finished Can Capabilities

Our modular gauge setups are unique and allow you to customise your gauge as and when you require, giving you the flexibility to ensure you have a total quality solution.

Torus Technology Group

Nedge Hill Science Park, Telford, Shropshire, TF33AJ, UK

Registered in England, Number 08664999